- BMW Group and PreZero sign strategic cooperation to develop scalable closed loop recycling for end of life vehicles across Europe

- Partnership targets reduced reliance on primary raw materials while improving supply chain resilience and compliance with EU circular economy priorities

- Collaboration combines automotive manufacturing data, recycling infrastructure, and battery recovery expertise to advance decarbonisation strategies

BMW Group and PreZero have launched a strategic cooperation aimed at reshaping how Europe’s automotive industry manages end of life vehicles and material recovery. The agreement, signed at the Innovation Park Artificial Intelligence campus, brings together vehicle manufacturing expertise and industrial scale recycling capabilities as regulators and investors intensify pressure on automakers to close resource loops.

The partnership focuses on creating a commercially viable model for recycling vehicles at the end of their lifecycle while keeping high value materials circulating within European supply chains. Executives from both companies framed the initiative as a response to rising material costs, geopolitical risk around raw materials, and the European Union’s push for circularity as a core industrial policy.

From Scrap Vehicles To Strategic Material Assets

At the center of the cooperation is a shift in how vehicles are viewed after retirement. Instead of being treated primarily as waste streams, end of life cars will be managed as strategic reservoirs of steel, aluminum, plastics, and battery components.

The companies plan to prioritize reuse first, keeping components in service wherever possible. Advanced recycling technologies will then target higher recovery rates for materials that can be reintroduced into manufacturing. This approach aims to reduce demand for primary raw materials, a key concern for automakers facing supply constraints tied to electrification and energy transition policies.

By building a closed loop system, BMW Group expects to strengthen supply chain resilience while reducing exposure to volatile commodity markets. Circularity is also positioned as a pathway to lower lifecycle emissions, aligning with European climate targets and emerging disclosure frameworks.

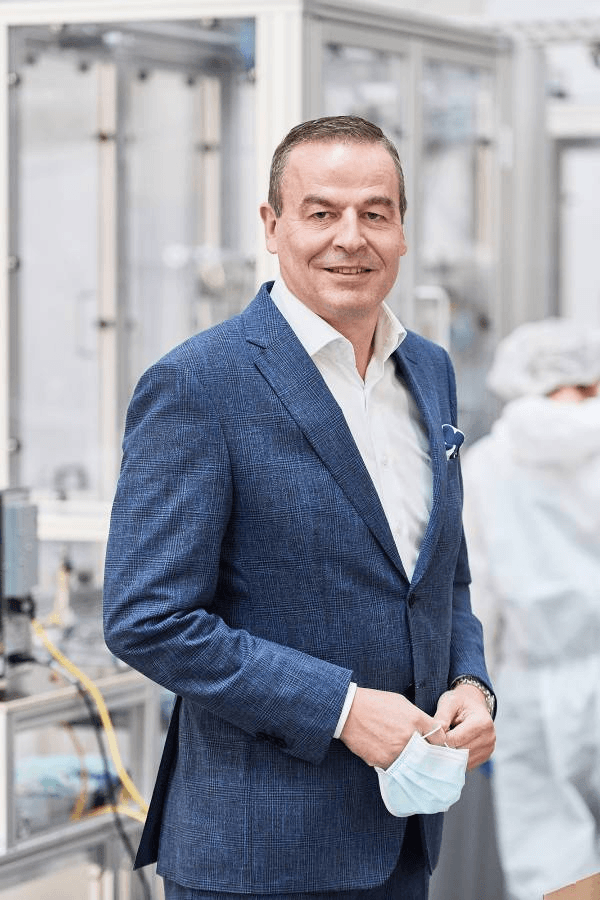

Ralf Hattler, Senior Vice President Customer Support and Aftersales BMW Group, said: “The collaboration with PreZero is another milestone on the road to establishing the circular economy as a genuine business model. For the BMW Group, circularity is already a central element of our corporate strategy and a key driver of CO2 reduction and resource efficiency. Together with PreZero, we are creating the conditions needed to design a vehicle’s entire value chain in a way that keeps materials and components of the highest quality in the loop for as long as possible. Our goal is to significantly reduce the need for primary materials and make supply chains more resilient.”

Building A Scalable Business Model For Circular Manufacturing

Beyond environmental goals, both companies emphasize the commercial dimension of the initiative. The collaboration will test recycling processes at industrial scale, develop new material flow management systems, and integrate data from production lines into dismantling and recovery operations.

BMW Group will contribute engineering insights from its Recycling and Dismantling Centre, including design for recycling principles that enable easier recovery of valuable materials. PreZero will bring expertise in European waste streams, advanced sorting technologies, and battery recycling infrastructure.

RELATED ARTICLE: BMW Group Presents Innovations Toward Sustainable Mobility

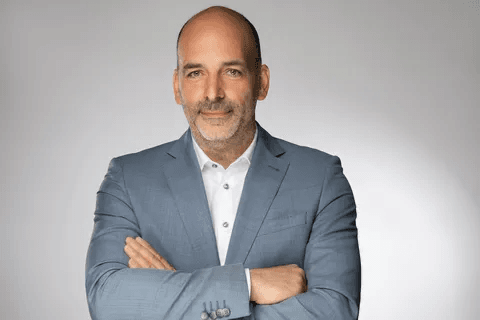

Carsten Dülfer, CEO of PreZero in Germany, said: “After acquiring Europe’s largest battery recycling facility last year, we are now taking the next step with the BMW Group towards establishing a functional circular economy in the automotive industry. Together, we are developing scalable solutions that not only meet strict compliance and sustainability requirements but also drive the decarbonisation of the industry across Europe. In this way, we are closing the gap between automotive development and the realities of recycling.”

Governance, Compliance, And EU Policy Alignment

The initiative arrives as European policymakers tighten circular economy requirements and expand producer responsibility rules across the automotive sector. Companies are increasingly expected to demonstrate how vehicles are designed, dismantled, and reintegrated into material cycles.

For investors and corporate leaders, the partnership reflects a broader shift in capital allocation toward resource efficiency strategies that address both climate targets and industrial competitiveness. Circular material flows are emerging as a governance priority as automakers navigate ESG reporting obligations, supply chain transparency demands, and rising scrutiny over resource extraction.

What Executives And Investors Should Watch

The cooperation between BMW Group and PreZero offers insight into how legacy manufacturers may adapt their business models as electrification accelerates and material scarcity grows. By embedding recycling into product design and lifecycle management, automakers aim to balance sustainability commitments with cost control and risk mitigation.

If successful, the model could influence supplier contracts, procurement strategies, and regulatory frameworks across Europe’s automotive ecosystem. Closed loop recycling systems may also reshape how companies value end of life assets, turning what was once a disposal challenge into a core pillar of industrial strategy.

As Europe pushes to reduce dependency on imported resources while advancing climate goals, partnerships that integrate manufacturing, recycling, and data driven logistics are likely to define the next phase of automotive transformation.

Follow ESG News on LinkedIn

The post BMW Group, PreZero Partner To Build Closed Loop Recycling Model For Europe’s Automotive Supply Chains appeared first on ESG News.