- Battery electric locomotives with 14.5MWh onboard storage will remove about one million litres of diesel consumption annually.

- Integrated solar, wind, transmission and battery storage infrastructure under Pilbara Energy Connect enables 24/7 renewable power for heavy-haul rail.

- Project advances Fortescue’s Real Zero target to eliminate Scope 1 and 2 emissions from Australian iron ore operations by 2030.

Fortescue has begun commissioning two battery electric locomotives on its Pilbara rail network, marking a decisive step in decarbonising one of the world’s largest iron ore supply chains. Delivered by Progress Rail, the locomotives will operate using renewable electricity supplied through the company’s Pilbara Energy Connect program, replacing diesel in heavy-haul rail operations.

Each locomotive houses a 14.5MWh battery, the largest ever deployed in a land-mobile application. Together they are expected to eliminate roughly one million litres of diesel consumption annually. Regenerative braking allows the trains to recover between 40 and 60 percent of energy during operation, improving efficiency across long-distance freight routes.

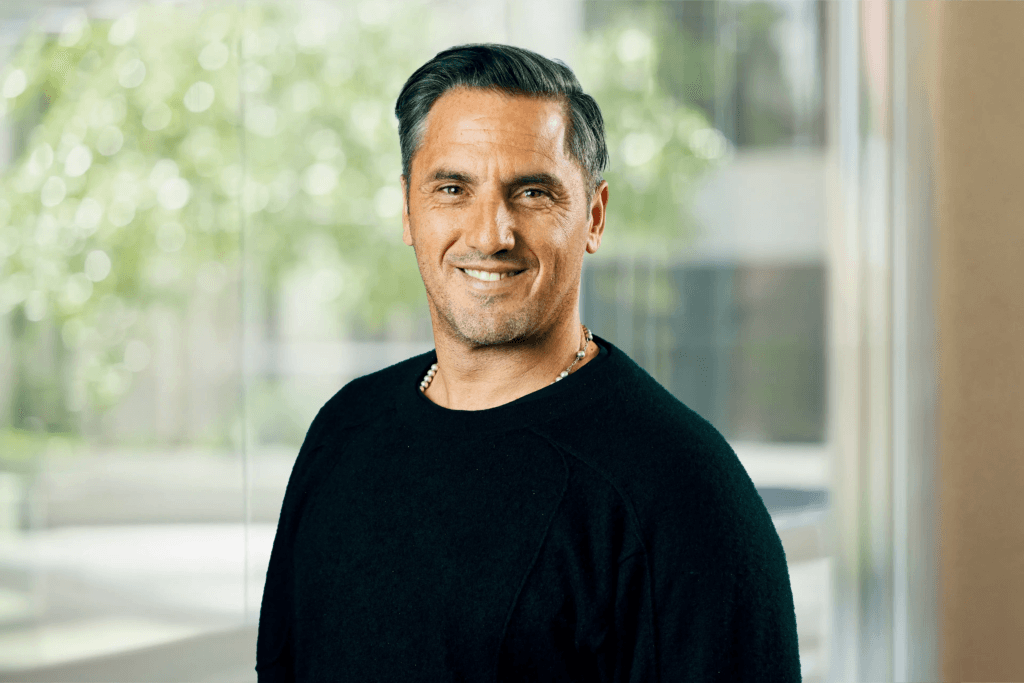

Fortescue Metals and Operations Chief Executive Officer Dino Otranto said the shift reflects a broader transformation in how the miner powers its operations.

“Real Zero is about transforming the way we power our assets, move our materials and run our operations, not offsetting emissions but eliminating them. Decarbonising our rail network is a critical part of that task and the commissioning of these battery electric locomotives demonstrates that heavy-haul rail can operate reliably without fossil fuels. For a mining operation of this scale, decarbonisation only works if renewable energy is firm, reliable and available 24/7. That’s why we’re building an integrated system combining large-scale solar and wind generation, battery storage and transmission infrastructure. Through Pilbara Energy Connect, we’ve already constructed more than 480 kilometres of high-voltage transmission lines, physically linking our energy assets to our operations and rail network. This infrastructure enables renewable power to replace diesel and gas, in real time, across the Pilbara.”

Renewable Backbone for Industrial Operations

The locomotives will draw power from Fortescue’s expanding renewable energy network. At North Star Junction, a 100MW solar farm is supported by a 250MWh battery energy storage system capable of delivering 50MW for up to five hours, stabilising supply for continuous operations.

Construction is advancing on the 190MW Cloudbreak Solar Farm, now about two-thirds complete. The company has also secured primary approvals for the Turner River Solar Farm, planned at up to 644MW, with construction expected to begin later this year. A further 440MW solar facility at Solomon remains in the near-term pipeline. Together these projects expand renewable capacity across the Pilbara and underpin Fortescue’s Real Zero pathway.

Fortescue Growth and Energy Chief Executive Officer Gus Pichot emphasized the central role of storage and digital optimisation in maintaining reliability.

“Battery storage is the backbone of a renewable-powered mining system. By integrating Fortescue Zero’s Elysia battery intelligence and management software, we’re able to optimise performance, extend battery life and intelligently balance energy across the network in real time. This technology ensures the right power is available at the right time – whether that’s supporting rail operations, smoothing solar output or maximising the value of stored energy.”

RELATED ARTICLE: Fortescue, China Baowu Launch Hydrogen Based Trial to Cut Steelmaking Emissions

Technology Partnership and Rail Innovation

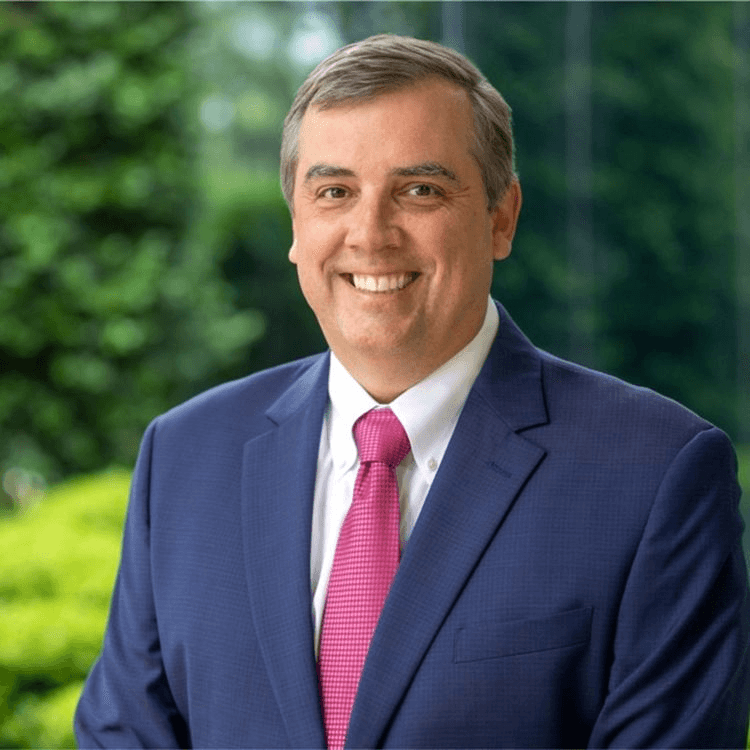

Progress Rail President and Chief Executive Officer John Newman framed the project as a demonstration of industrial collaboration.

“Our relationship with Fortescue reflects what is possible when two organisations share a commitment to advancing the future of rail. We are proud to deliver rail solutions that help our customers meet their toughest challenges, and we look forward to continuing to deliver products that enhance safety, reliability, and sustainable performance across the rail network.”

Scaling Decarbonisation Across the Pilbara

The rail electrification initiative forms part of a broader decarbonisation push across Fortescue’s Pilbara operations. Recent milestones include construction of the Nullagine Wind Project, deployment of electric mining equipment including an electric drill and 12 electric excavators, and strategic partnerships supporting large-scale deployment of renewable generation and electrified heavy machinery. The company has also invested in next-generation wind technology through the acquisition of Nabrawind.

Fortescue’s Climate Transition Plan sets out its commitment to eliminate Scope 1 and 2 emissions from its Australian terrestrial iron ore operations by 2030. For mining companies, policymakers and investors, the Pilbara rollout offers a working model of how electrification, renewable energy integration and digital energy management can decarbonise heavy industry without compromising reliability or output.

As resource producers face mounting pressure to align with global climate targets, Fortescue’s integrated energy and transport strategy highlights the scale of infrastructure, capital and technological coordination required to decarbonise industrial supply chains worldwide.

Follow ESG News on LinkedIn

The post Fortescue Launches Battery Electric Rail Fleet Powered by Renewables appeared first on ESG News.