Metals and mining corporation Rio Tinto and steel producer Salzgitter announced today a new partnership, to work together towards carbon-free steelmaking. Under a new Memorandum of Understanding, the companies have agreed to explore the optimization of Rio Tinto’s products iron ore pellets, lump and fines for use in Salzgitter’s SALCOS green steel project in Germany.

Steelmaking is one of the biggest emitters of CO2 globally, with total greenhouse gas emissions (GHG) from the sector accounting for 7% – 9% of direct emissions from the global use of fossil fuels. As manufacturers globally aim to decarbonize their supply chains, demand for steel produced using fossil-free energy is expected to increase significantly.

Ulrich Grethe, Salzgitter Flachstahl GmbH Chairman of the Management Board, said:

“With this alliance, we want to combine the knowledge of both companies to make further progress with low-carbon steel production.”

Salzgitter’s SALCOS green steel project in Germany targets virtually carbon-free steel production through the use of hydrogen direct reduction, in which iron ore is heated with the aid of hydrogen, instead of coal which is typically used in blast furnaces. Salzgitter aims to have its first direct reduction plant in operation as soon as 2026, and the company expects to gradually replace its carbon-based blast furnace route with direct reduction plants.

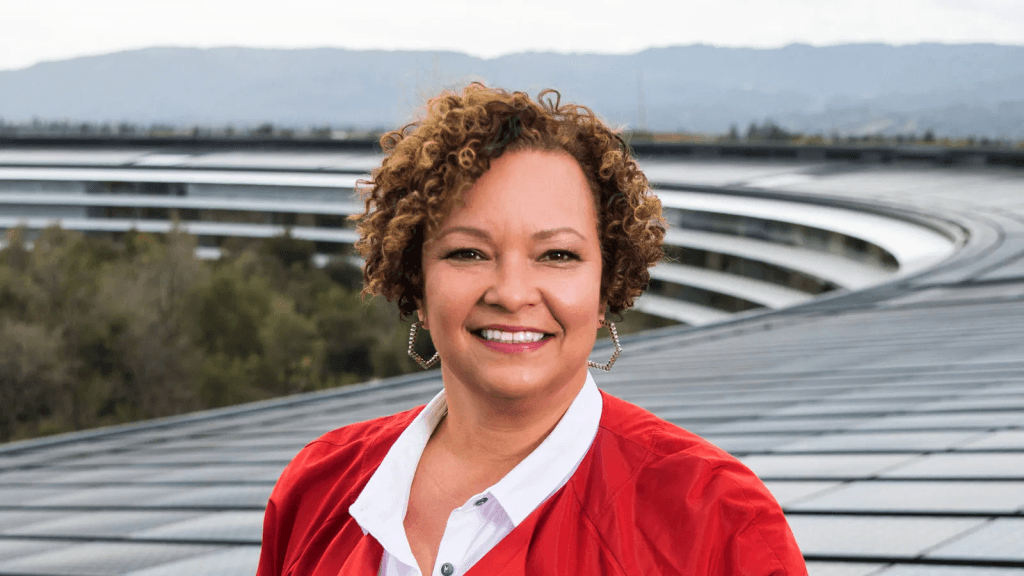

Alf Barrios, Rio Tinto Chief Commercial Officer, said:

“We welcome the chance to work with Salzgitter on ways to accelerate green steelmaking, in keeping with our commitment to reduce emissions across the steel value chain. Salzgitter has one of the world’s most advanced green steelmaking projects. Rio Tinto is excited at the opportunity of supplying our product and combining our technical expertise with that of Salzgitter to help advance the SALCOS project.”

The post Rio Tinto, Salzgitter Launch Green Steel Partnership appeared first on ESG Today.